Celmet™ Metal Foam

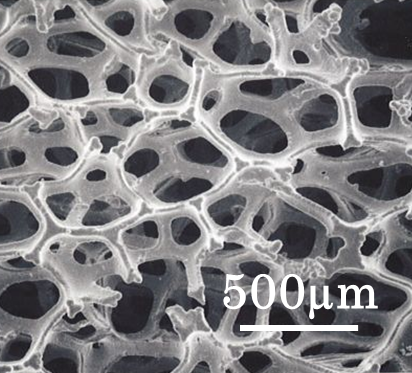

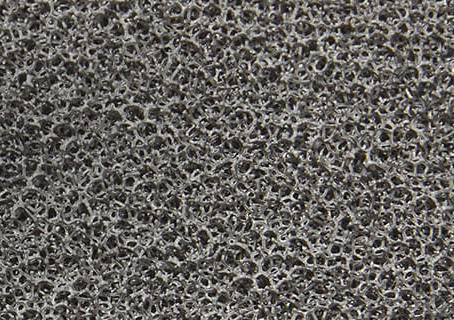

Celmet™ consists of a porous metal frame with a three–dimensional, sponge–like structure, made with materials such as Ni (nickel) and alloys of Ni–Cr, Ni–Sn, as well as Al and Cu which are currently under development.

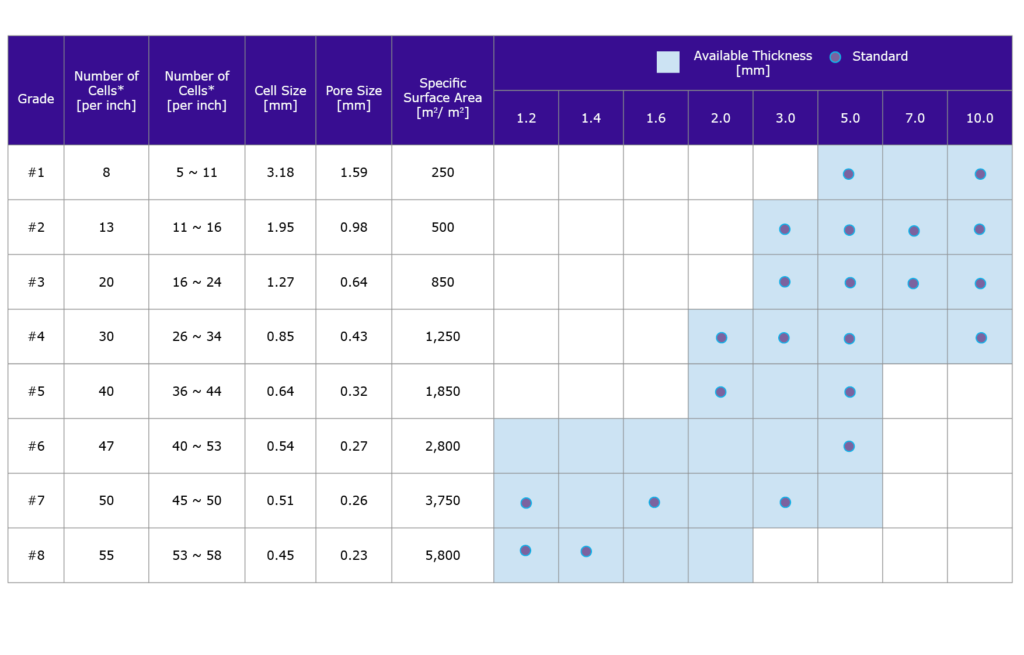

Compared to sintered metal and metal fiber, Celmet™ has much higher porosity and elasticity, with cell sizes ranging across 8 levels, from 0.45mm to 3.2mm.

Utilising its excellent workability for easy processing such as cutting and pressing, Celmet™ has been extensively adopted as electrodes of Ni–MH batteries for hybrid vehicles.

In the emerging “hydrogen society”, Celmet™ is expected to be widely applied to new applications, such as structural parts of fuel cell for stationary and automotive uses, as well as electrodes of hydrogen generators, etc. With the world’s largest production plant, Sumitomo are proud and prepared to contribute to the global environment and energy infrastructure.

Features

Properties

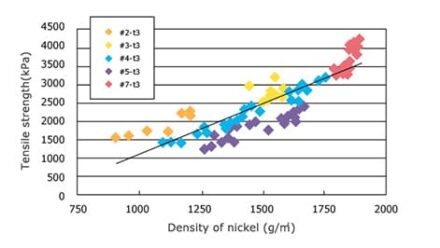

Tensile Strength (Nickel Celmet™)

Tensile strength is proportional to the nickel density, regardless of the cell size.

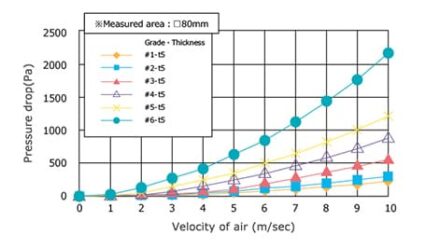

Pressure Drop (Nickel Celmet™)

By choosing the part number and thickness, you can optimise the pressure loss.

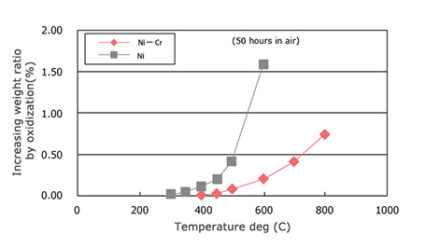

Heat Resistance (Oxidisation)

Operating temperature limit:

- Ni: 450-500 deg.

- Ni-Cr: 650-700 deg.

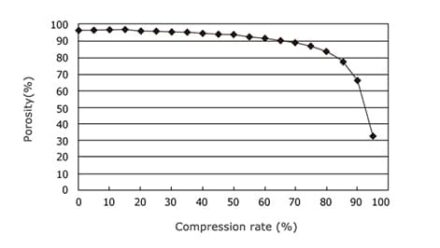

Relationship between Porosity and Compression Rate

Even when pressed down to half the thickness, the porosity is kept at 90%.

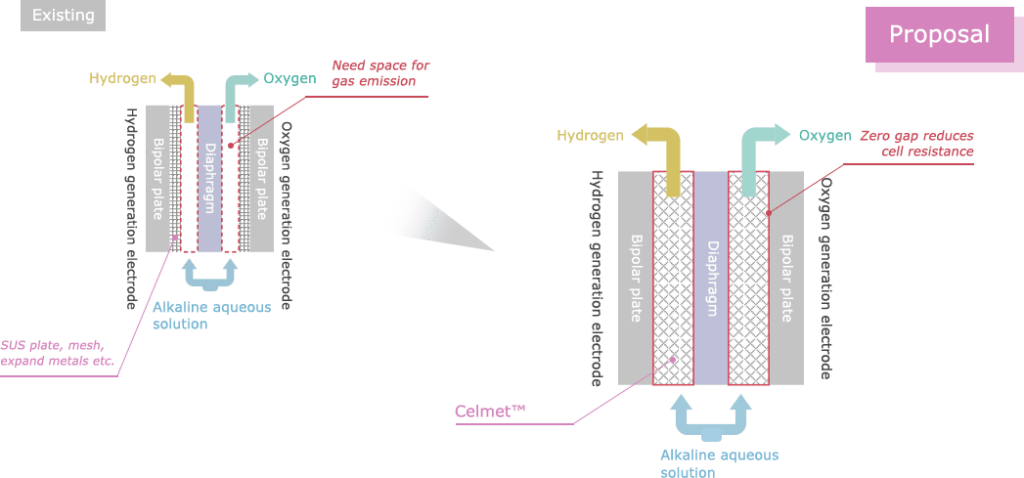

Electrodes of Alkali Water Electrolysis

Celmet™ has been considered as industrial hydrogen generator.

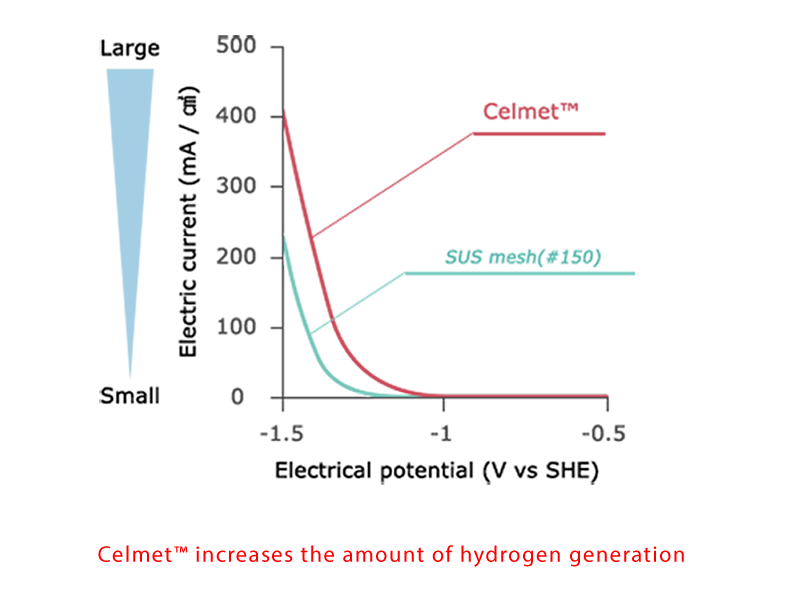

Current Voltage Characteristics of Hydrogen Generation Electrode

Benefits of Applying Celmet™

| Property | Specification |

|---|---|

| Voltage reduction of alkaline water electrode cell | Celmet™ is porous metal so that a zero-gap structure is possible and can reduce resistance of solution. |

| Improvement of hydrogen generation efficiency | Compared to lath or mesh, applying Celmet™ to hydrogen electrode can increase the amount of hydrogen, without increasing the cell voltage due to its large surface area. |

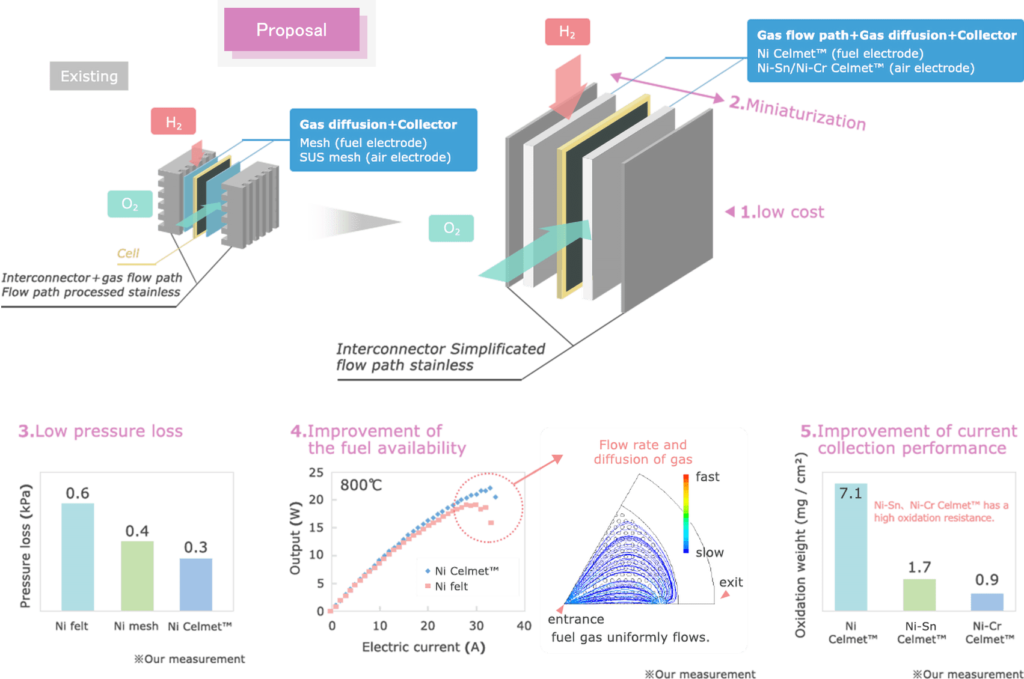

Fuel Cells (SOFC)

Celmet™ has been adopted as current collector and gas flow path of industrial and institutional fuel cells.

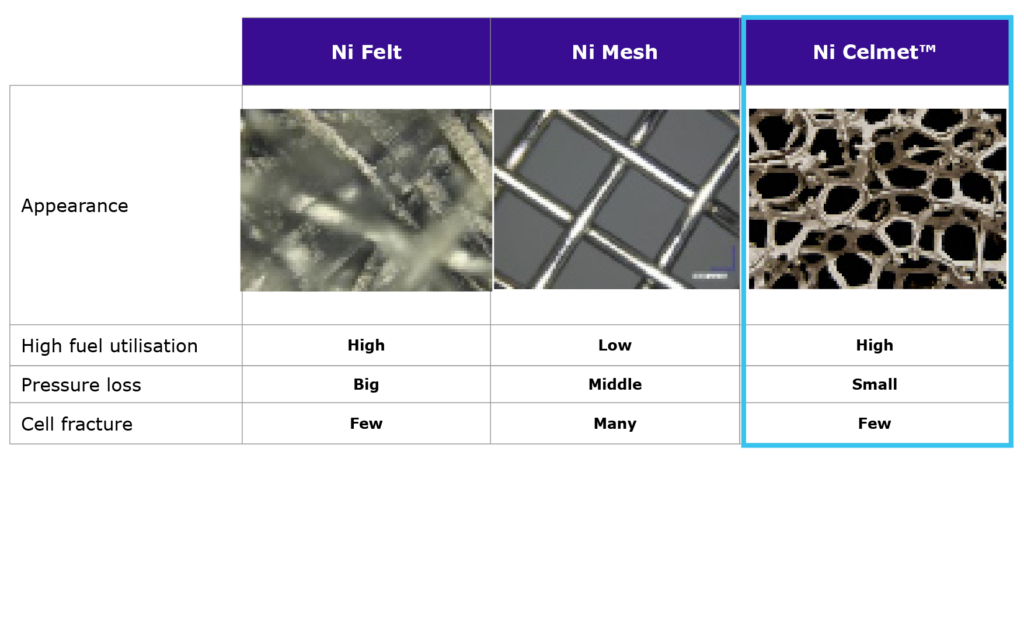

SOFC Performance of Various Anode Materials

Benefits of Applying Celmet™

| Property | Specification |

|---|---|

| Low cost stack | No need for complex gas flow. |

| Compact stack | Celmet™ can make interconnector thinner so that Celmet™ functions as gas flow path and gas diffusion. |

| Reduction of pressure loss | High porosity can reduce pressure loss. |

| Improvement of the fuel availability | Celmet™ can improve the fuel availability because fuel gas flows uniformly. |

| Improvement of current collection performance of air electrode | Ni alloy Celmet™ can be applied as air electrode, because it has good oxidation resistance. |

Fuel Cells (PEFC)

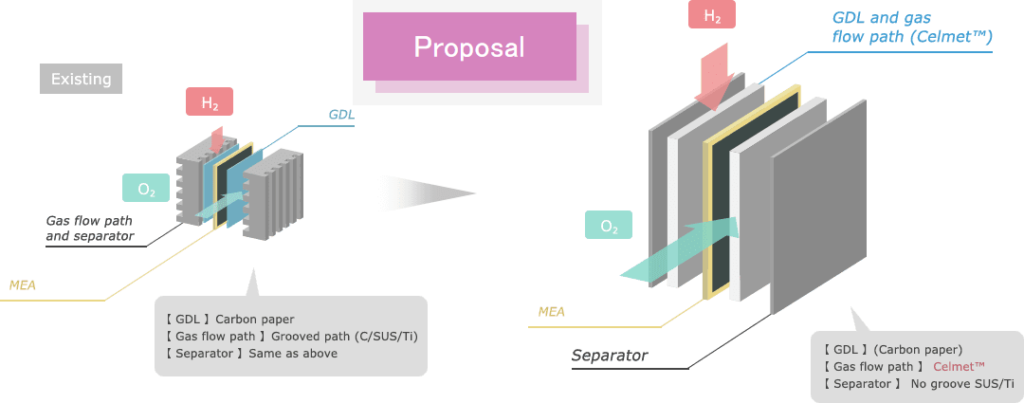

Celmet™ has been adopted as current collector and gas flow path of fuel cells for lift trucks.

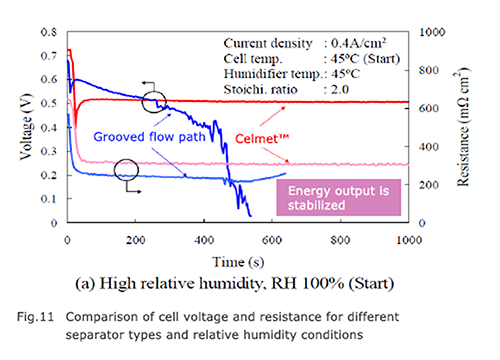

Energy Output Characteristics*

Analysis of performance characteristics and internal phenomena of PEFC with porous flow field, transactions of the Japan Society of Mechanical Engineers, Vol.78, No789, 204-212.

Benefits of Applying Celmet™

| Property | Specification |

|---|---|

| Low cost | No need for GDL and separators with complex gas flow path and lower pressure loss. |

| Compact | Celmet™ functions as gas flow path, gas diffusion and current collector. |

| Performance improvement | Lower resistance and high-strength compared to carbon paper. |

| Higher energy output | Higher current collection performance and improved flooding resistance – drainage is improved by capillary of Celmet™. |

How to Buy

To find out how we can support you, please Contact Us.